Aris

Integración de monitoreo y vigilancia geotécnica para rajos, botaderos, pilas y tranque

Cargando 0%

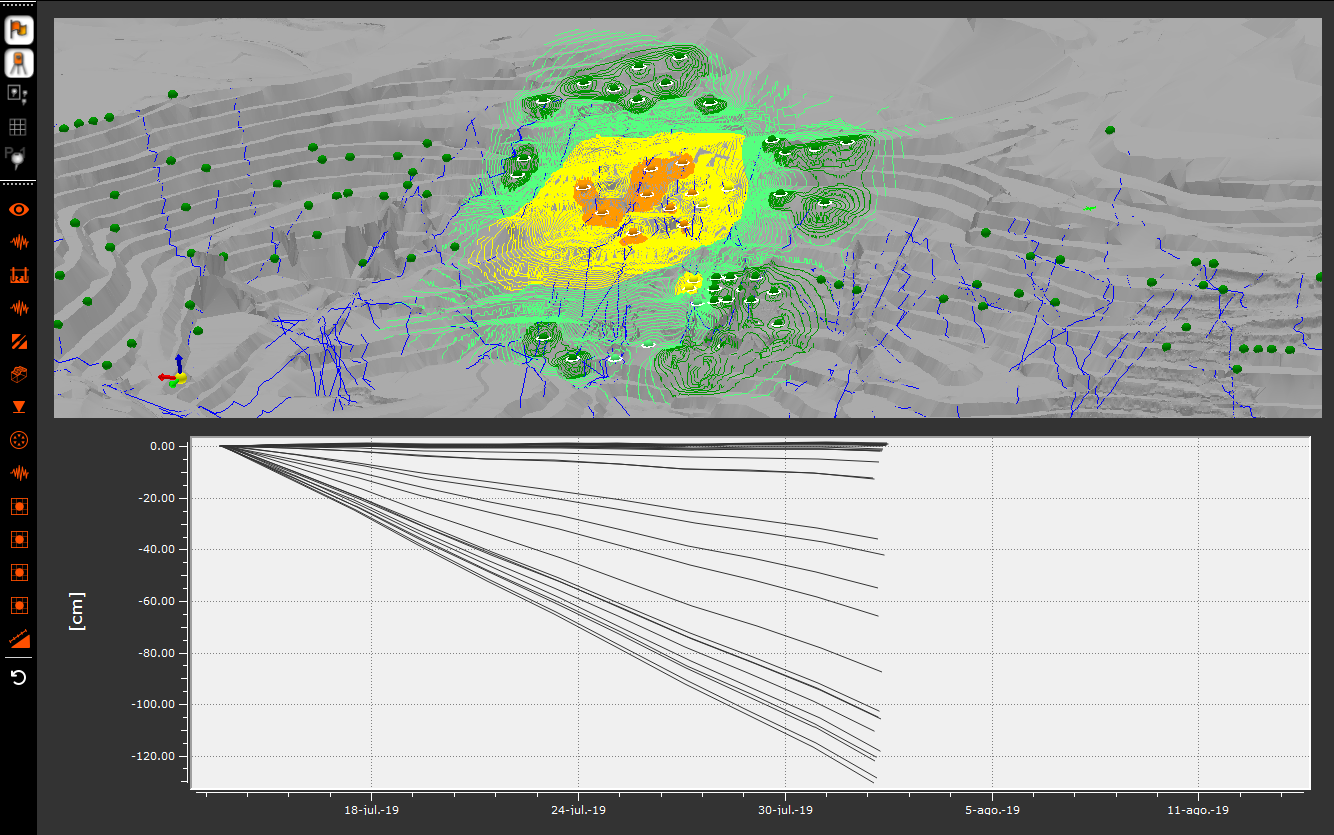

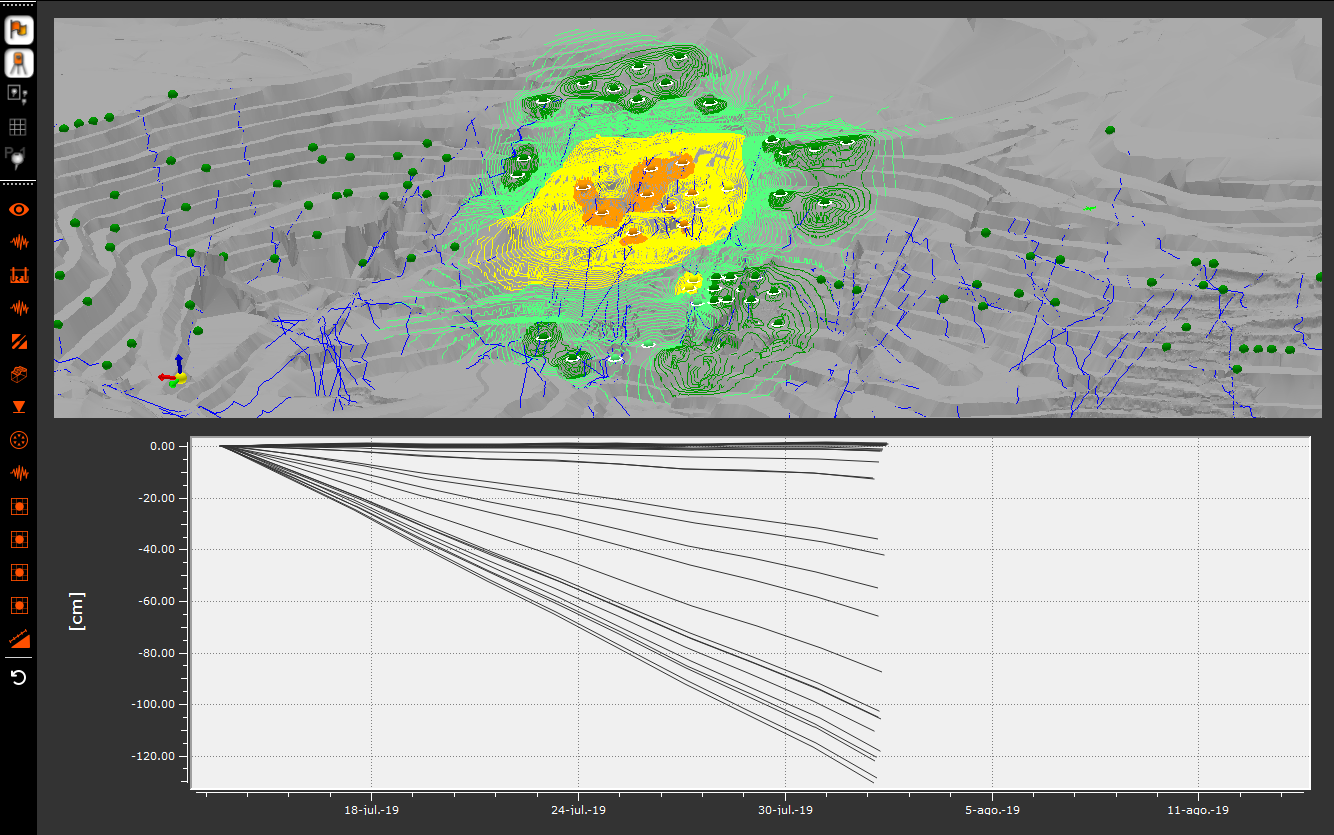

DELTA realiza la conciliación espacial del plan minero automáticamente a partir de topografías reales y planificadas. Monitoreo de desviaciones del plan de forma sencilla y ágil

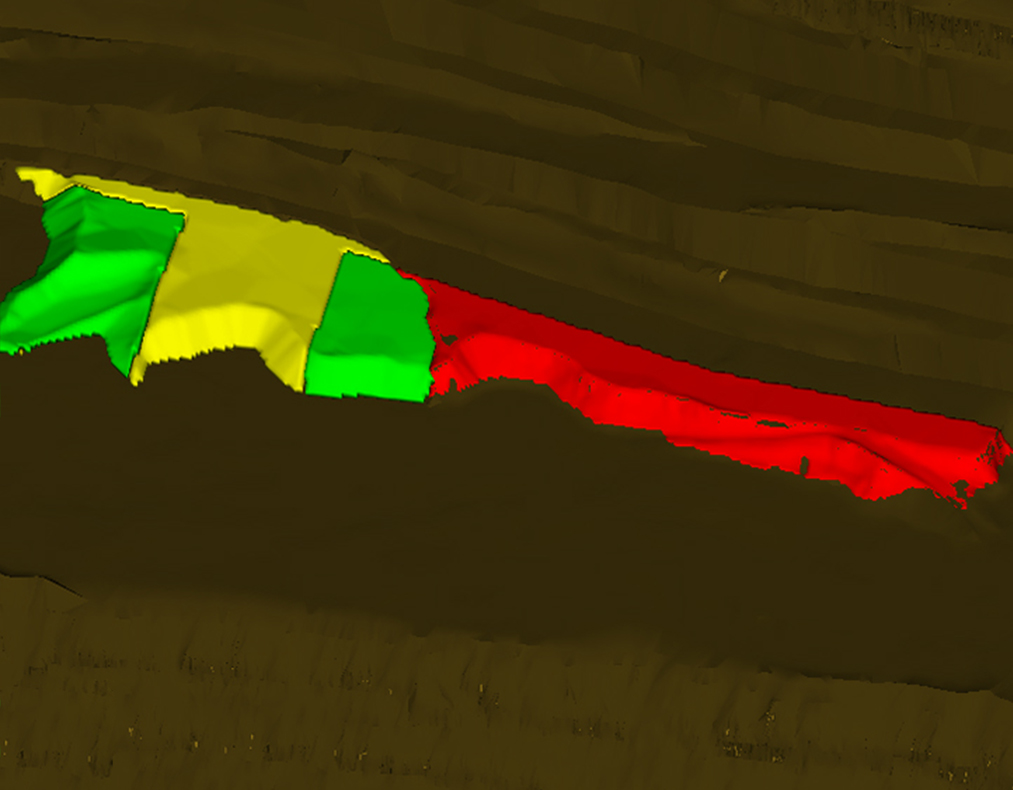

DELTA es un software que permite identificar y monitorear desviaciones en la secuencia del plan minero a partir de topografías reales y topografías, o sólidos, del plan. DELTA realiza automáticamente los cálculos de cumplimiento espacial y entrega resultados categorizados para un posterior análisis fácil y rápido

DELTA es un software orientado a planificadores e ingenieros de control y reconciliación descontentos con el esfuerzo y la calidad del proceso de conciliación espacial de planes. Además, su interfaz intuitiva y amigable con el usuario permite un uso rápido y fácil

Calcula automáticamente las diferencias de volumen entre las condiciones iniciales y finales de la mina en un periodo definido, asignando categorías de cumplimiento del plan. Genera outputs exportables para cada una de las categorías de cumplimiento del plan minero, compatibles con otros softwares de planificación minera usados comúnmente

Permite definir fases acotadas para localizar los cálculos según el usuario lo requiera, proporcionando la capacidad de obtener reportes comparables entre distintos sectores de la mina

Con DELTA, es posible obtener resultados cubicados considerando el modelo de bloques en una corta cantidad de tiempo gracias a la agilidad y facilidad de uso del software

La generación de topografías proyectadas deja de ser un problema con Delta: obtén la topografía final de un periodo o una secuencia multi periodo, a partir de la superficie inicial y los avances planificados

En este módulo podemos monitorear, reportar y almacenar los resultados del cumplimiento de los planes mineros mensuales y el presupuesto anual en un ambiente 3D. Los inputs y los resultados se almacenan en una base de datos única que se va actualizando con la nueva información mensualmente y que permite reportar vía PDF directamente.

DELTA también permite la visualización de resultados en sección transversal; personalización de las categorías del reporte; Importar/Exportar zonas definidas para cálculo; Triangulación de topografías de líneas; Corte de topografías; cambio de formato de archivos de triangulaciones; Compatibilidad con software de planificación minera

El tiempo dependerá directamente del tamaño de los inputs, sin embargo, normalmente el proceso tarda entre 1 y 5 minutos.

Para utilizar las funcionalidades de DELTA se debe disponer, al menos de:

- Topografías planificadas de inicio y fin

- Topografías reales de inicio y fin

- Modelo de bloques

- Volúmenes de extracción planificados.

El tiempo dependerá directamente de los inputs, gracias a su facilidad de uso, obtener un reporte de adherencia al plan no debería tardar mas de 10 minutos para cualquier usuario.

DELTA puede leer archivos de extensiones .00t (vulcan) y .msr (minesight), sin embargo, se permite sólo la escritura de archivos .00t

• Procesador: Intel Core i3-2100 o superior. Recomendado Intel Core i5-6500 o superior

• Memoria RAM: 8 GB mínimo. Recomendado 16 GB o más.

• Disco duro: 250 GB mínimo. Recomendado 500 GB o más.

• Sistema operativo: Windows 8 versión 64 bits o superior.

• Gráficos: Nvidia Fx5500 256mb o superior. Recomendado Nvidia GeForce GT 430 1GB o superior.

• Pantalla: Resolución mínima 1366x768 pixeles.

• Periféricos: Mouse óptico.

Los formatos de lectura de DELTA son:

- Archivos .dwg

- Archivos .dxf (triangulaciones o líneas)

- Archivos .obj

- Archivos .00t (formato de Maptek Vulcan)

- Archivos .msr (Formato de Minesight)

- Archivos .csv (para modelos de bloques)

Y los formatos de escritura son:

- Archivos .dxf

- Archivos .obj

- Archivos .00t

Sólo se puede recortar las topografías o archivos cargados, DELTA no funciona como un editor 3D

Si, es posible monitorear y almacenar los datos anuales de conciliación espacial de los planes de corto plazo y Budget

Revisa nuestras diferentes soluciones de data analytics y simulación que ayudan a tomar mejores decisiones en Planificación, Geotecnia, Excelencia Operacional, y Operaciones Mina

Integración de monitoreo y vigilancia geotécnica para rajos, botaderos, pilas y tranque