TIMining Aware

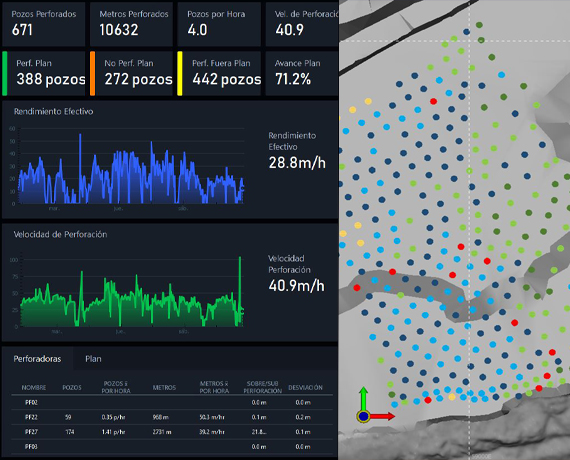

Aumenta el cumplimiento del plan y las velocidades promedio con el monitoreo de estos KPIs en tiempo real

Cargando 0%

Mejora los resultados del proceso de perforación y tronadura a través del monitoreo en línea del avance del plan de perforación, rendimiento de los equipos, y la detección automática de desviaciones del proceso.

TIMining Drillit es un software de gestión del proceso de perforación y tronadura en tiempo real que permite monitorear las desviaciones del proceso, así como también el estado de avance y cumplimiento del plan de perforación. Drillit realiza un QC automático de las perforaciones y carguío de explosivos, y muestra en línea el estado, rendimiento y trayectoria de las perforadoras. Además, tiene una APP para Supervisores de terreno que permite tener datos en tiempo real en cualquier punto de la mina.

Drillit transforma los datos del proceso de perforación y tronadura en información y conocimiento para la toma de decisiones de corto plazo, de manera altamente visual y con una interfaz rápida e intuitiva

Drillit se conecta automáticamente a los sistemas de gestión de los equipos de perforación, a los datos de carguío de explosivos y otros sistemas de información. Estos datos son filtrados, procesados y transformados en información y conocimiento georreferenciado y altamente visual.

Drillit indica el estado de avance del plan de perforación y las fechas estimadas de término para cada polígono. Así, sabrás cuándo se podrá cargar explosivos y podrás tomar decisiones inmediatas para aumentar el cumplimiento del plan semanal.

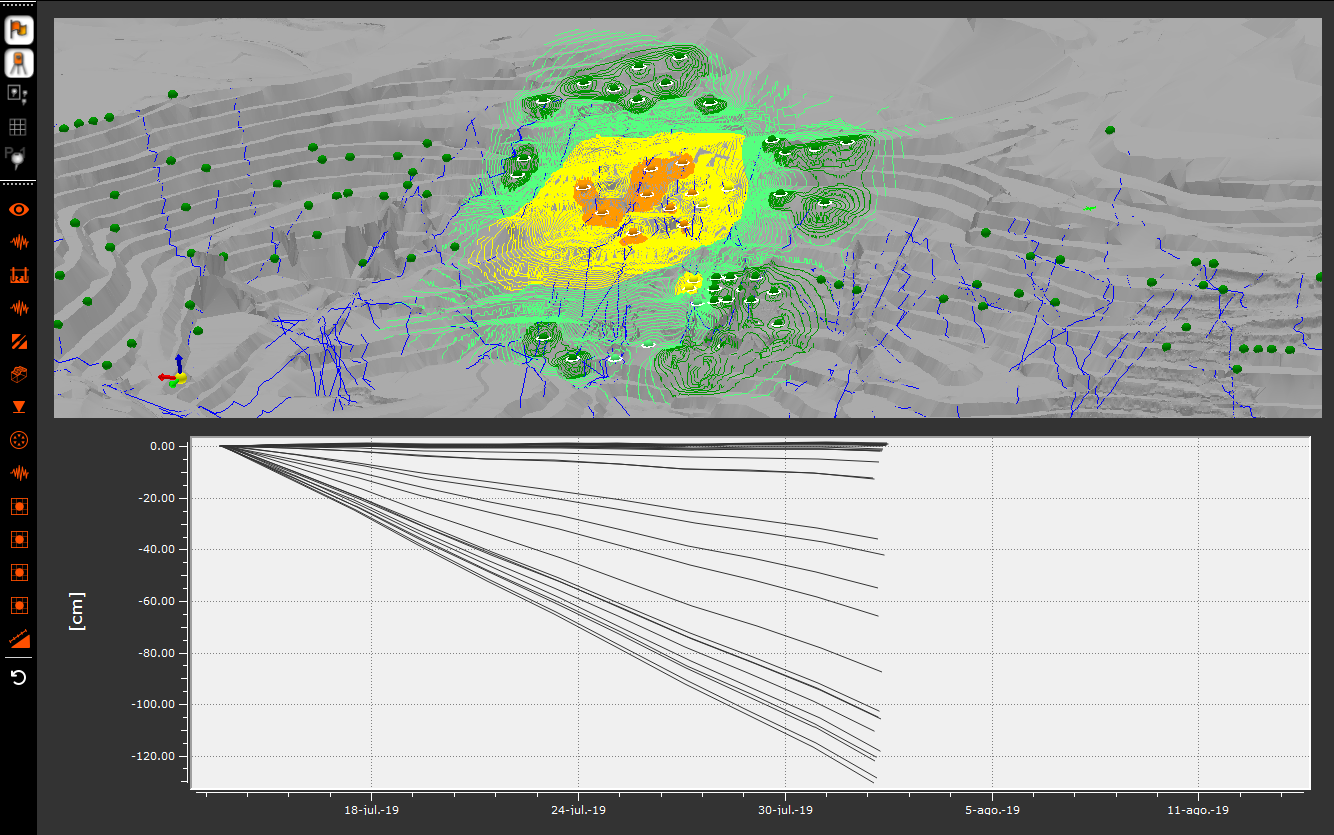

Drillit detecta automáticamente las desviaciones de calidad en la perforación y la carga de explosivos, indicando de forma georreferenciada dónde están ocurriendo y enviando alertas en tiempo real.

Además del control de calidad, Drillit ofrece un completo set de vistas georreferenciadas para apoyar la toma de decisiones: mapa de densidad de pozos, velocidades de perforación, cumplimiento del plan de perforación, mapa de densidad de explosivo, modelo de bloques (UGT).

Con Drillit puedes ver el estado, rendimiento, disponibilidad y utilización de la flota de perforación dentro del turno o día a día.

Drillit te permite visualizar rápidamente las zonas sobre o sub cargadas de explosivos, para poder ajustar la carga de las siguientes tronaduras en el corto plazo.

Drillit muestra información de detalle de cada pozo: desviaciones en el collar y largo, duración de la perforación, parámetros operacionales centímetro a centímetro (RPM, Pulldown, Bit Air Pressure, Torque, Tasa de Penetración), explosivo cargado y presencia de agua.

Los supervisores de terreno pueden acceder en tiempo real a indicadores del proceso: estado, ubicación y rendimiento de las perforadoras, pozos perforados las últimas 24 horas, cumplimiento del plan y desviaciones de calidad.

Puedes visualizar todos los equipos de perforación que se encuentren conectados a una base de datos. Estos pueden ser tanto de producción o precorte.

Se requiere tener acceso a los datos de los sistemas de navegación de las perforadoras. Es ideal tener acceso a planes de perforación, carguío de explosivos, modelo de bloques y topografías actualizadas de la mina

Drillit se integra con los principales sistemas de perforación y de gestión de flota: Surface Manager Epiroc, ProVision Modular Mining, Fleet Terrain Caterpillar, Wenco Systems, Jigsaw, VIST, entre otros. Además, se puede conectar a cualquier tipo de fuente de información

Drillit tiene la capacidad de monitorear en tiempo real. Si los sistemas de navegación actualizan sus datos al servidor minuto a minuto, la información en Drillit también se actualizará minuto a minuto. El monitoreo dependerá de la frecuencia de actualización de estos sistemas

Con Drillit puedes revisar el control de calidad de las perforaciones, tanto las desviaciones de collar (x,y) como del largo de los pozos (z); y controlar el carguío de explosivos (conciliación tipo y cantidad de explosivo)

Drillit muestra múltiples indicadores del proceso: velocidad de perforación, rendimiento efectivo, utilización y disponibilidad de la flota, desviaciones de calidad respecto del diseño, parámetros operacionales (RPM, Torque, Bit Air Pressure y Pulldown), cumplimiento y desviaciones del plan

Drillit apoya a usuarios de diferentes niveles: Superintendentes, Ingenieros Especialistas P&T/QAQC y Supervisores de Terreno

Drillit funciona en computadores móviles o de escritorio con requerimientos mínimos de resolución de pantalla (1920x1080)

Drillit funciona en cualquier modelo y sistema operativo de teléfono smartphone

Con Drillit puedes apoyar el Short Interval Control del proceso de perforación y tronadura al estar conectado en tiempo real a lo que está sucediendo en la faena. Puedes monitorear minuto a minuto y recibir alertas sobre desviaciones al proceso para poder tomar decisiones preventivas y correctivas para aumentar la calidad del proceso

Revisa nuestras diferentes soluciones de data analytics y simulación que ayudan a tomar mejores decisiones en Planificación, Geotecnia, Excelencia Operacional, y Operaciones Mina

Aumenta el cumplimiento del plan y las velocidades promedio con el monitoreo de estos KPIs en tiempo real

Integración de monitoreo y vigilancia geotécnica para rajos, botaderos, pilas y tranque