Mejores taludes mediante detección de desviaciones y aplicación de mejores prácticas

Overview

Con el objetivo de disponer de antecedentes para asegurar la estabilidad, seguridad y el beneficio económico de los taludes, desde 2015, Minera Antucoya controla el logro de la construcción de las paredes del rajo utilizando dos métricas: El Factor de Diseño, para evaluar el cumplimiento de los parámetros de diseño; y el Factor de Condición, para dar cuenta del daño y estado de saneamiento de las caras de los bancos.

El seguimiento y control de la construcción del talud, permitió un aumento de la seguridad y continuidad operacional, a partir de la implementación de nuevas prácticas definidas en un trabajo conjunto entre los equipos de Geotecnia, de Perforación & Tronadura y de Carguío & Transporte, las que han mejorado el cumplimiento del Ancho de Berma de los bancos, minimizando el peligro de accidentes por caída de rocas desde los bancos superiores.

Solución

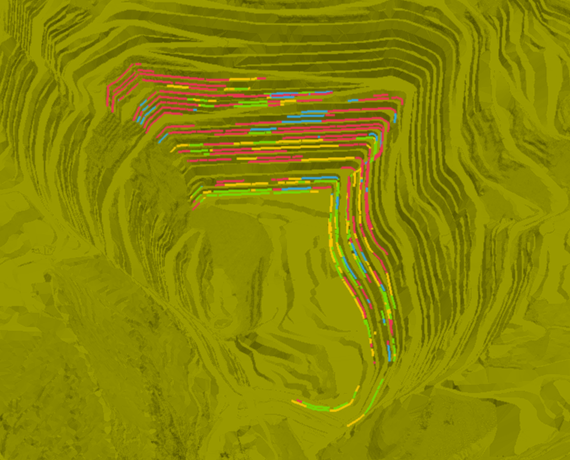

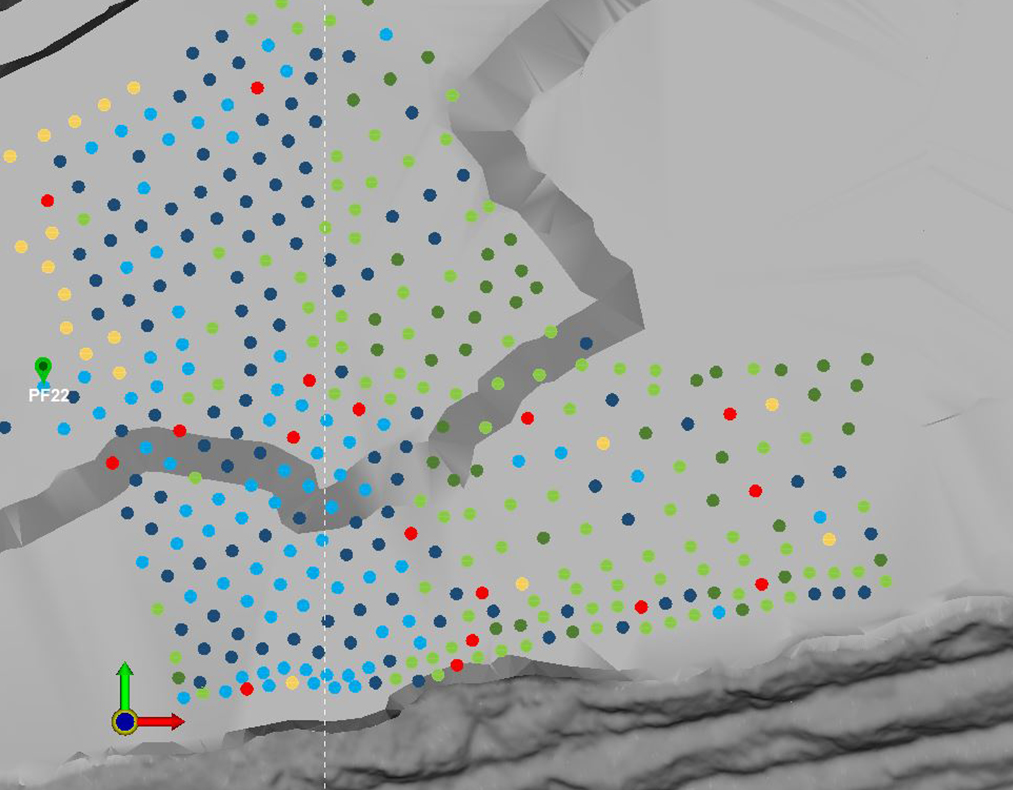

El seguimiento, control y análisis del cumplimiento de la construcción de los taludes, utilizando Timining – Sict, considera:

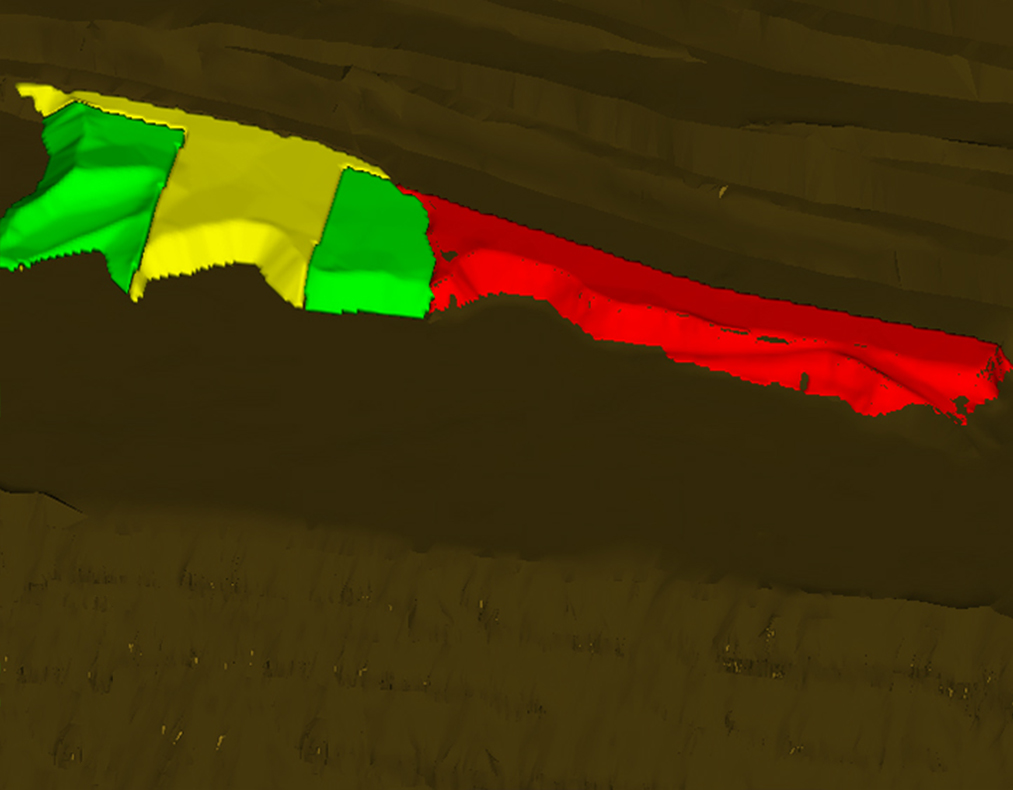

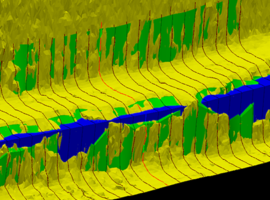

- Uso del Factor de Diseño para evaluar parámetros de diseño tales como: Ancho de Berma, Ángulo Cara de Banco, Línea de Programa, etc

- Evaluación del Factor de Condición mediante el mapeo de elementos como la presencia de medias cañas, el fracturamiento de la cresta, la existencia de sobreexcavación en la pata o la presencia de bloques inestables, entre otros.

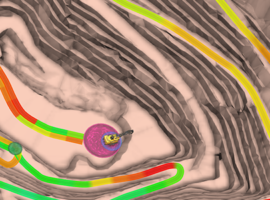

- Identificación y ubicación de las desviaciones en el cumplimiento del diseño y la calidad de las caras de los bancos.

- Análisis de los elementos que condicionan el buen o mal resultado de la construcción de los bancos, a partir de la correlación del cumplimiento con el modelo geotécnico-estructural y las prácticas de construcción de taludes

- Revisión de los resultados del análisis en conjunto con el equipo de la Superintendencia de Perforación y Tronadura, para confirmar las causas de las desviaciones y definir colaborativamente las modificaciones al proceso, con el objetivo de lograr mejores taludes.

Utilizando esta metodología, la compañía adquirió una herramienta para la evaluación conjunta entre Geotecnia y Perforación y Tronadura, cuya interacción ha permitido mejorar el diseño de las tronaduras de pared final, introduciendo las siguientes modificaciones:

- Se alejaron los pozos de producción de la futura cresta del banco inferior

- Se estableció una pasadura negativa en los pozos buffer (fondo de pozo sobre la cota del futuro nivel de piso).

- Cambio de la configuración de carga de la fila buffer (se quita el taco)

Impacto

Los cambios en las prácticas de perforación y tronadura derivados de la implementación de esta metodología, han producido el siguiente impacto:

- Aumento de la capacidad de retención de los bancos construidos, dado por un incremento del 13% en el Ancho de Berma; pasando de un promedio de 6,27m a 7,11m en el 4° trimestre de 2019.

- Sensibilización de las Superintendencias involucradas en la construcción del rajo, hacia el objetivo común de mejorar el cumplimiento de los parámetros de diseño y el trabajo colaborativo.

- Mejora de los remates de caja y línea de programa, a partir de capacitaciones y retroalimentación objetiva a operadores de la Superintendencia de Carguío y Transporte.

Por último, cabe señalar que la mejora obtenida ha validado la metodología y a SICT como herramienta.

“La implementación de SICT nos ha permitido detectar oportunamente desviaciones en la construcción de bancos y visualizarlo de manera sencilla y georreferenciada, con lo cual se ha facilitado la comunicación con las distintas áreas, impactando positivamente en el logro de las bermas de los bancos construidos en Antucoya”

Boris Duarte, Geotécnico Senior, Minera Antucoya.

PRODUCTOS RELACIONADOS

Drillit

Monitoreo del proceso de Perforación y Tronadura, QA/QC automático y conciliación de los planes de perforación.