QA QC del proceso de perforación automático y en línea

Overview

Hasta 2019 el proceso de Quality Control (QC) de Perforación requería un alto nivel de procesamiento y análisis de datos y no existía posibilidad de tener los datos en línea para toma de decisiones oportunas ante desviaciones en la ejecución de este proceso.

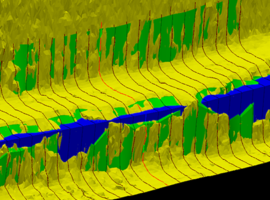

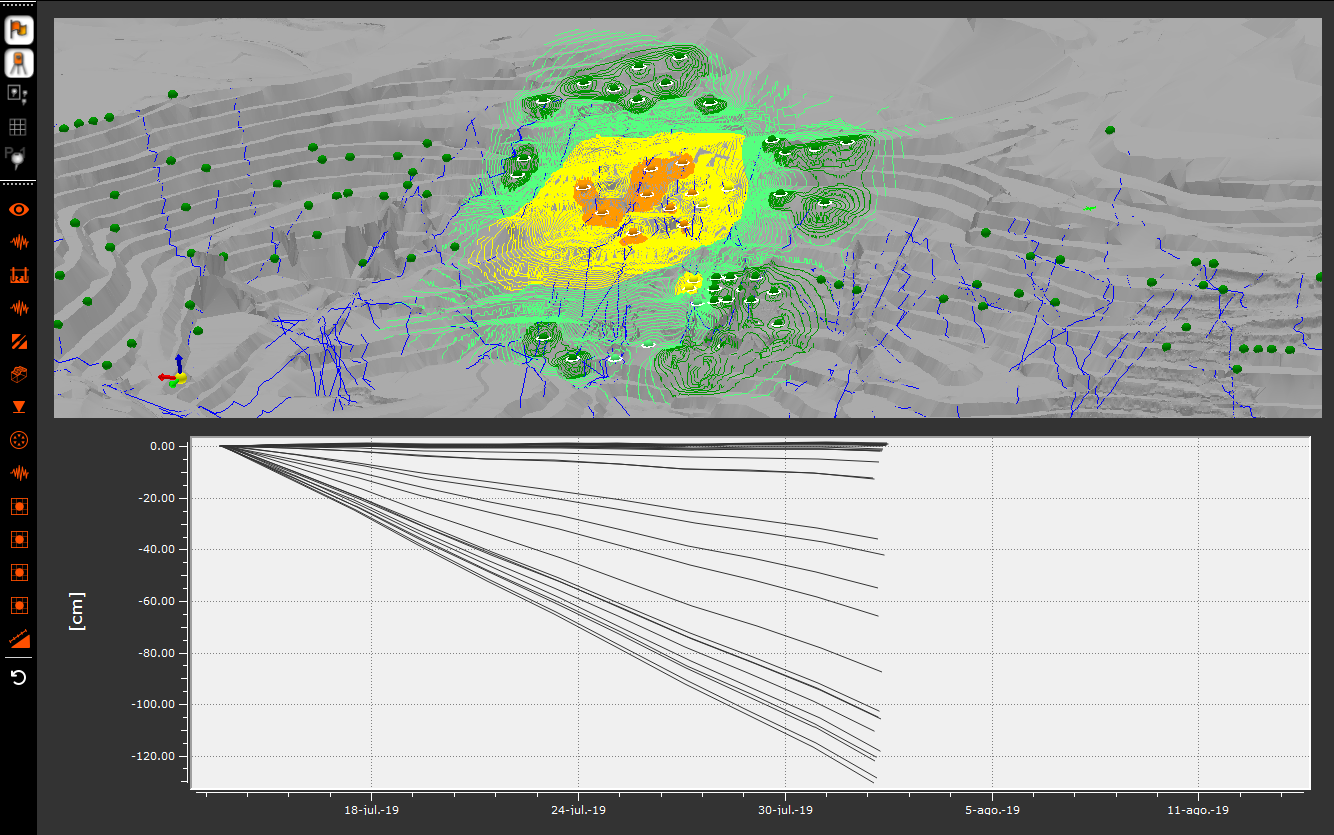

El QC en línea permite controlar sobre y sub perforación, desviación de collar de pozos, cantidad de repasos, velocidad de perforación, parámetros operacionales (RPM, torque, Pulldown, presión de aire), contrastar con unidades geotécnicas, utilización efectiva en base disponible, disponibilidad y estados de los equipos.

Solución

Durante 2019 la Superintendencia de Perforación y Tronadura trabajó en conjunto con TIMining desarrollando un sistema que automatizara e integrara en línea la información del proceso de Perforación, desplegando esta información en tiempo real. En julio de 2019 se implementó el software Drillit y se capacitó a los supervisores del área de perforación y tronadura. Gracias a este trabajo hoy es posible:

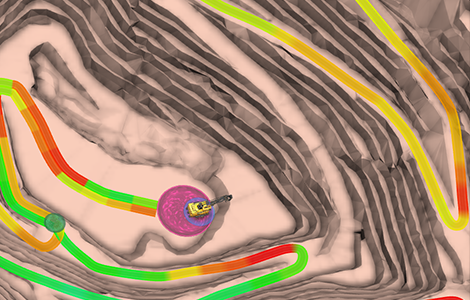

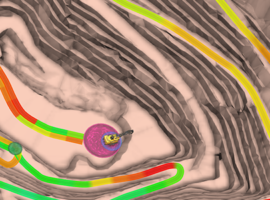

- Visualizar en tiempo real el estado y posición de los equipos de Perforación

- Ver el cumplimiento del plan en tiempo real

- Identificar inmediatamente desviaciones de collar y longitud de la perforación

- Tener información de pozos reperforados en línea

- Conocer el rendimiento y estado del proceso en terreno vía la app para teléfonos

- Visualizar el tracking de perforadoras

Impacto

Los beneficios de la implementación de este software son lograr la granulometría esperada, construcción de los taludes de acuerdo a diseño, eficiencia, seguridad y menor costo del proceso:

- Potencial de 4000 metros de perforación en 1 mes gracias a mejor secuencia de perforación

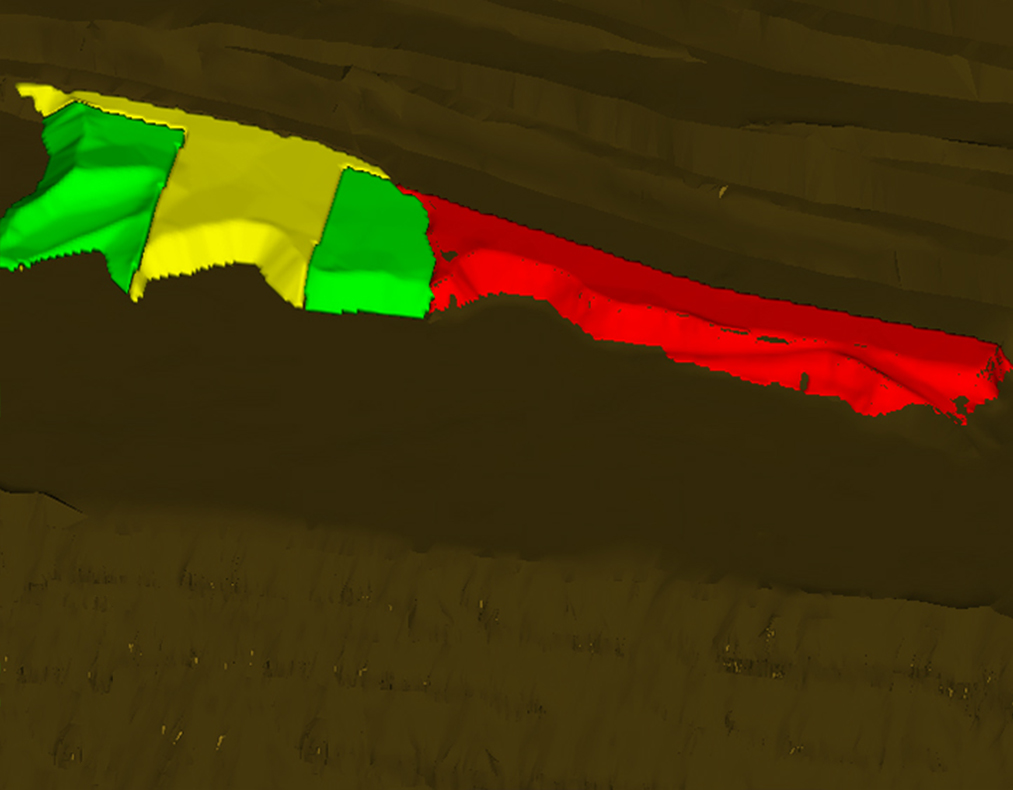

- Detección de anomalías dentro de una misma UGT con mapa isovelocidad en tiempo real

- Disminución de sobre/sub perforación

- Disminución de desviación de pozos: se identifican zonas con mayor o menor densidad de pozos en línea

- Controlar los rangos de parámetros operacionales en RPM, Pulldown, Torque y Presión de Aire en tiempo real

- Estado de operación o mantención de la flota en línea

PRODUCTOS RELACIONADOS

Aris

Integración de monitoreo y vigilancia geotécnica para rajos, botaderos, pilas y tranque